MIMAKI INDIA PRIVATE LIMITED

Case Study

Mimaki user stories

Challenges

Improvements

They use a laser cutting machine for material cutting, but when cutting life-size panels made of aluminum composite panels, the cut edges melted due to heat, resulting in an unsightly finish. Additionally, they handle other materials that laser cutting struggles with, such as thin sheet films and styrene boards. They were searching for a cutting plotter capable of handling these materials.

CFX does not burn the cross section like laser cut, and a satisfactory finish is obtained.Since it has a dragonfly reading function, there is no slight positional deviation when cutting.Therefore, it is also useful for cutting small printed matters such as seals, stickers, and product mounting paper. The range of in-house manufacturing has expanded and it has become possible to meet various requests.

Product installed

Challenges

Improvements

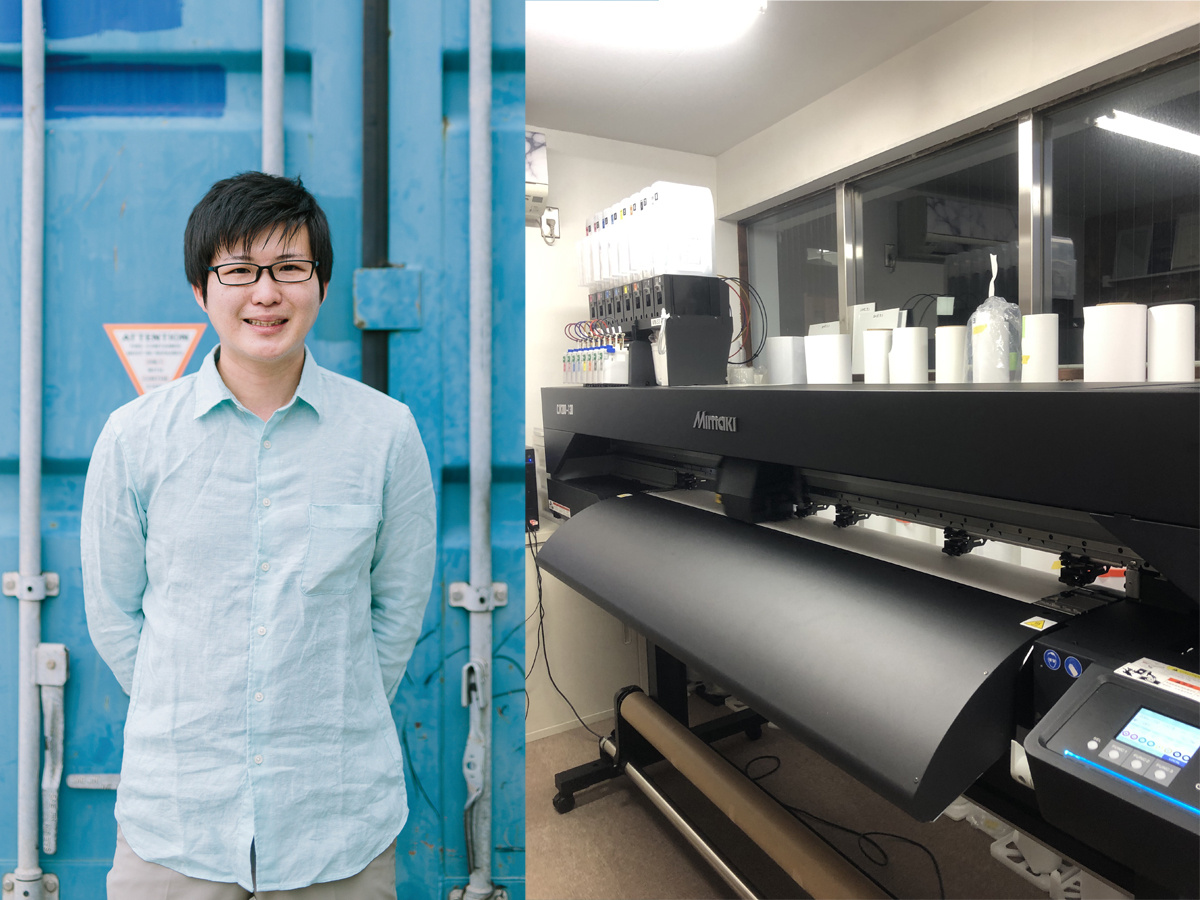

At SAN GRAPHICA Inc., while the "CJV300" had delivered high-quality printing, the expanding range of production materials necessitated more stable high-resolution output and improved workflow efficiency. Additionally, the ability to operate within limited installation space and the ease of operation and manageability even with a small staff were key points when considering equipment upgrades.

The introduction of the "CJV200" maintains the same high image quality while further improving color reproduction and detail stability. Its compact size and simple operation allow it to fit seamlessly into any workspace, streamlining daily tasks. Furthermore, low-odor ink and a system for monitoring operational status create an environment where even small teams can operate with confidence.

Product installed

The Illusory Space Created by Digital Prints at Okinawa Kingyo Museum: Linoarqx Co., Ltd.

Challenges

Improvements

While strongly drawn to the potential of digital print wallpaper, he lacked both print knowledge and equipment. Existing design wallpapers either didn't match his vision or were prohibitively expensive, presenting challenges in finding options to achieve the desired expression.

The quick-drying properties of the UV ink for the "UCJV300-160" enhance on-site responsiveness. Combined with the "Artista," it enables wallpaper installation tailored to customer budgets. In addition to wallpaper, he built a production environment with enhanced expressive capabilities by utilizing multi-layer printing and gloss effects.

Product installed

Challenges

Improvements

The existing cutting plotter could not cut rubber with thickness and hardness precisely. The area of the processing table was also small, and they wanted to increase the production efficiency. Since large products need to be made in sections and the labor of bonding occurs after cutting, they wanted to reduce the cost by processing them as a single piece.

Because CFX has a high cutting pressure and a large processing table, high-quality rubber products can now be mass-produced. Large materials can be cut only once, reducing the number of bonding steps. The processing speed is also fast so that they can handle urgent cases with plenty of time. Now that the company has more work to do, it can develop new businesses.

Product installed

Challenges

Improvements

Printing on special materials and expensive materials with restrictions on materials and shapes involved time and risk in preparing jigs and printing from trial manufacture to actual production, and it was difficult to propose sales.

The introduction of a UV-DTF printer eliminates the need for jigs and allows a wide range of materials to be handled, reducing the time required for trial manufacture. The transfer sheet method has a high degree of freedom and contributes to shortening delivery times and winning new projects. The understanding of the sales field has advanced, and the ability to respond to not only order goods but also signature related matters has been greatly improved.

Product installed

Challenges

Improvements

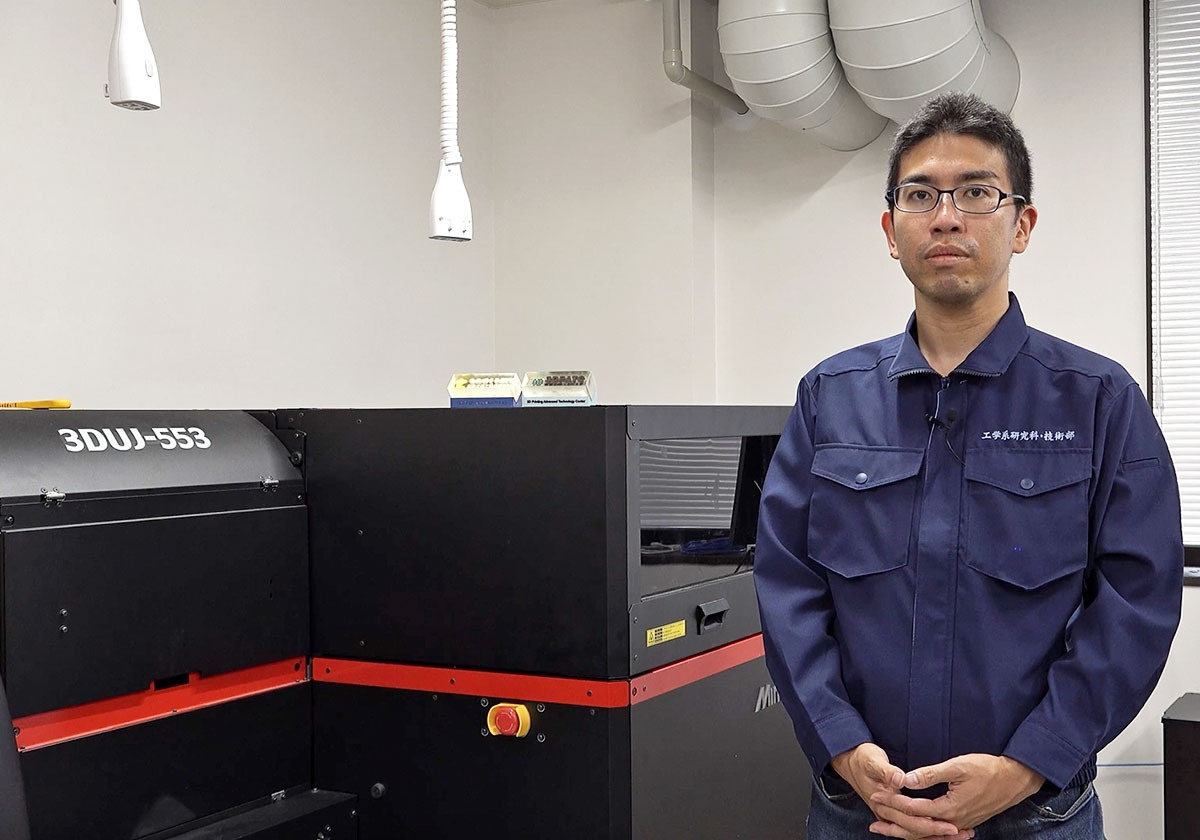

In addition to output by 3D printer, post-processing such as polishing and coloring was time-consuming. Also, the hue were not very good and sometimes the finished product was not as desired.

The size of the output at a time was increased, greatly reducing labor and time. Output could be done at a level that did not require post-processing such as scraping off and polishing. In addition, coloring work is no longer necessary and colors can be expressed as they are in the 3D data, expanding the range of applications and making it possible to realize a variety of offers.

Product installed

How Mimaki’s Full Color 3D Printer is Revolutionizing the Footwear Design Process

Challenges

Improvements

In the design and development of new products for footwear brands, it took more than a month from the time the order was placed to the time the prototypes were received. Also, it was taking time for the design idea to take shape and be put in the hands of the designer.

With the 3DUJ-553, a 3D design model of a shoe can be printed in one to two days, significantly shortening the time required to create a prototype, which normally takes more than one month. In addition, the process from design modification to prototype production can be repeated more times in a short period, leading to better product creation.

Product installed

Fansea creates unique virtual and 3D printed memorabilia using Mimaki technology

Challenges

Improvements

The business of the German start-up company Fansea is based on 3D asset creation, web3 and metaverse consultancy. Fansea was searching for a technology to bridge the gap between the virtual and physical by offering their customers photorealistic, 3D copies of their digital assets.

3DUJ-553 can accurately bring the individual qualities of each item directly from the screen to the model. 3D printing has the potential to revolutionise the digital space.

Product installed

Challenges

Improvements

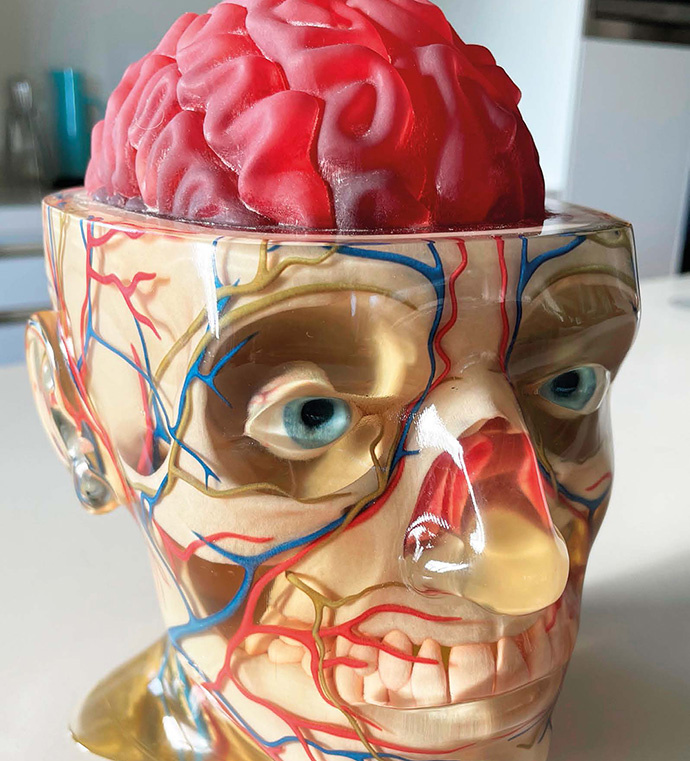

Low color accuracy, fragile parts, and time intensive post processing produced less than desirable results with powder based full-color 3D printing.

The full-color 3DUJ-553 creates robust anatomical models with realistic color reproduction that are easy to post process.

Product installed

Challenges

Improvements

When necessary, the Creative Design and Additive Manufacturing Lab at the University of Auckland added color to 3D prints by hand due to the lack of vibrant colors and affordability in full-color 3D printers.

The Mimaki 3DUJ-553 full-color 3D printer now allows the Lab to print in 10-million colors at a running cost affordable to the university.

Product installed