MIMAKI INDIA PRIVATE LIMITED

Case Study

Mimaki user stories

Marketiger B.V. (Eindhoven, Netherlands) | 3D Printer Special website

Challenges

Improvements

I started my 3D business with monochromatic 3D printers, but was struggling to keep up with demand due to the amount of post processing involved to add color. We examined a powder based full-color 3D printer, but found that the material was too fragile and the color faded within one year, so we decided it wasn't the right option for us.

The introduction of 3DUJ-553 eliminated the need for manual coloring work and made it possible to create molded objects in a short time with materials that had rich color expression.

Product installed

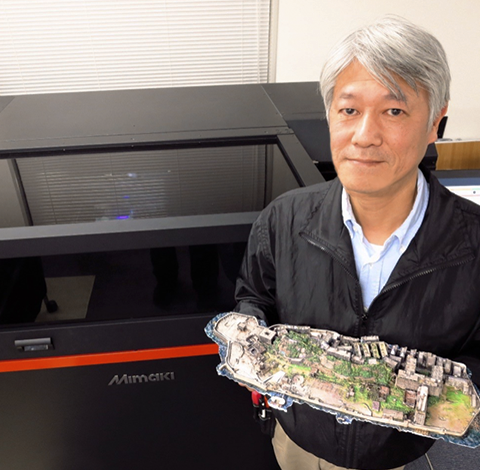

Okumura Design Corporation (Nagoya City, Aichi) | 3D Printer Special website

Challenges

Improvements

We were looking for 3D printers capable of outputting high definition 3D data created in the office for use in explaining construction processes to our clients.

The model prototypes were extremely popular and we successfully landed requests for proposals. As 3D printers can reproduce models cheaply in diverse scales, they are better than outsourcing hand-crafted models, and we are confident they will become indispensable as effective business tools.

Product installed

Hotaru Corporation Co., Ltd. (Osaka-shi, Osaka) | 3D Printer Special website

Challenges

Improvements

Although the company already had a full-color 3D printer, the plaster-based type needed to go through processes that almost required artisan skills such as polishing and re-coloring for modeled objects before they become products.

3DUJ-553 has enabled more than 10-million color representation that is fine in details, in addition to real, delicate expression that needs no re-coloring. As the support material is water-soluble, we can remove it easily by soaking the object in water, which allows us to work on details to the last minute, enabling a wider range of expression than ever before.

Product installed

JMC Corporation (Yokohama, Kanagawa) | 3D Printer Special website

Challenges

Improvements

Although we already had a plaster-based full-color 3D printer, we did not accept orders with colors because it was extremely difficult to finish the works with colors satisfactory to clients. However, our valued client requested us to deliver figures finished with colors.

3DUJ-553 is highly valued by clients for its excellent color reproducibility. Because there is no need to provide coloring experts and thus 3D-printed products can be delivered as finished items, the company has propelled the business a step ahead without making unnecessary investment.

Product installed

B&P Co.,Ltd. (Osaka-shi, Osaka) | 3D Printer Special website

Challenges

Improvements

We wanted opportunities to meet new clients of different types, such as those ordering large-size posters and signs, POP display for promotion.

We came to receive orders and sample requests from companies manufacturing souvenirs, amenities and original goods, resulting in acquisition of new clients.

Product installed

The Future of Printing with Mimaki Engineering's TRAPIS: Kori Tokyo Store

Challenges

Improvements

Sublimation transfer printing is limited to polyester, so they would like to create an environment where they can print on a wider variety of fabrics.

The introduction of TRAPIS enables printing on nylon, synthetic leather, blended fabric, and mixed woven fabric. It was also adopted by a famous designer brand and received high praise. Currently focusing on BtoB printing orders triggered by commercialization of own brand.

Product installed

Challenges

Improvements

Entering the sign market to expand their business base, they wanted to have machines from a manufacturer that can provide everything in-house and has a proven record.

Both speed and quality were much better than expected, and the colors were outstanding. They have never had a machine that prints so smoothly, including the feel of operation. Generous support at the employee level within the company allows us to use the machine with peace of mind.

Product installed

Challenges

Improvements

The amount of orders for deformed floor seats and life-size panel production is increasing year by year and overtime is a matter of course in the busy season. They wanted to automate the process of cutting large base materials, because there were some cases where the site was overcapacity at times and they had to turn down jobs that our sales staff had won.

Reduced the dependency on individuals of the work and labor costs have been reduced by about 15% since the introduction of CFX. Even during the peak season, they were able to get through without overtime and without turning down a single job. In addition, the defect rate was improved, and the introduction of additional equipment was considered only three months after the introduction.

Product installed

Challenges

Improvements

The JV300 they had been using for many years had been deterioration and they wanted to replace it with a printer with higher specifications.

Satisfied with the output speed and density of white ink. Printing speed does not slow down even when printing with more passes than before, and the results are clear and beautiful. The JV330's new "Media Changer" feature is fully utilized to greatly increase productivity.

Product installed

Challenges

Improvements

Want to improve their cutting skills and efficiency.

After the introduction of CFX, the amount of work that can be cut in a day has greatly increased, and the total amount of work that can be ordered has increased, so sales and profits have increased. In addition, overtime hours have decreased, and employee satisfaction is high. Seeking further efficiency, table expansion was decided in five months after the introduction of the main body.

Product installed