MIMAKI INDIA PRIVATE LIMITED

Case Study

Collaboration

Efforts of Mimaki

Support ski jumper Sara Takanashi with merchandise made using UV-DTF printers!

We printed the "JUMP for the Earth PROJECT" logo on a ready-made tumbler using the UV-DTF printer "UJV300DTF-75" and presented them to Sara Takanashi.

Product used

Challenges

Improvements

Printing on special materials and expensive materials with restrictions on materials and shapes involved time and risk in preparing jigs and printing from trial manufacture to actual production, and it was difficult to propose sales.

The introduction of a UV-DTF printer eliminates the need for jigs and allows a wide range of materials to be handled, reducing the time required for trial manufacture. The transfer sheet method has a high degree of freedom and contributes to shortening delivery times and winning new projects. The understanding of the sales field has advanced, and the ability to respond to not only order goods but also signature related matters has been greatly improved.

Product installed

The Future of Printing with Mimaki Engineering's TRAPIS: Kori Tokyo Store

Challenges

Improvements

Sublimation transfer printing is limited to polyester, so they would like to create an environment where they can print on a wider variety of fabrics.

The introduction of TRAPIS enables printing on nylon, synthetic leather, blended fabric, and mixed woven fabric. It was also adopted by a famous designer brand and received high praise. Currently focusing on BtoB printing orders triggered by commercialization of own brand.

Product installed

Challenges

Improvements

Need a machine with high productivity and high cutting accuracy for apparel applications.

When they were using other companies' machine, they experienced cutting discrepancies or lack of cutting, but the CJV150 covered all the problems. The vividness of the colors is highly evaluated by customers, and they are also satisfied with Mimaki's support system.

Product installed

Challenges

Improvements

They were having trouble keeping a large inventory of products in stock.

Switching to in-house UV printing on plain materials eliminated inventory concerns. The business has steadily expanded, and now offers fabric printing, acrylic coating, and other services in addition to goods production using approx. 40 UV machines.

Product installed

Challenges

Improvements

The COVID-19 made it imperative to develop new sales channels.

Purchased sublimation transfer printers, UV printers, laminators, cutting plotters, etc., and launched an in-house manufacturing and sales business specializing in sports-related goods to meet detailed needs.

Product installed

Challenges

Improvements

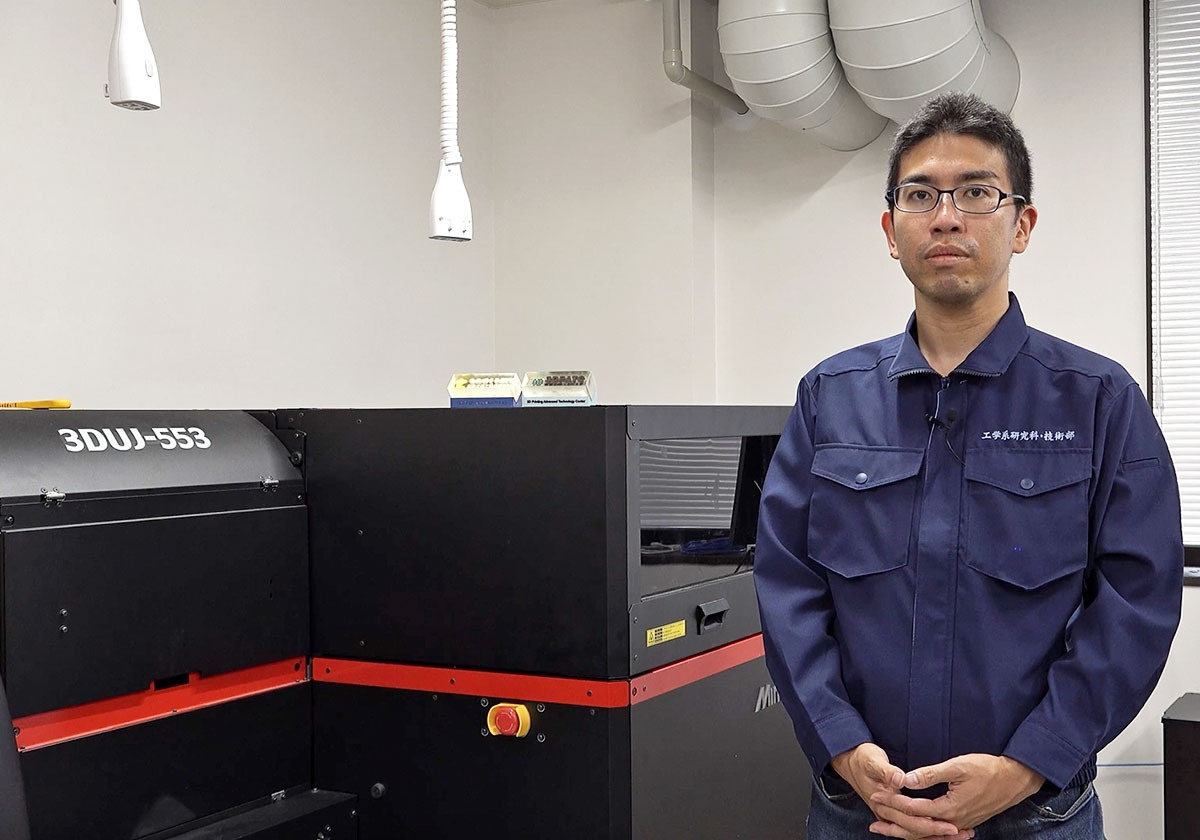

In addition to output by 3D printer, post-processing such as polishing and coloring was time-consuming. Also, the hue were not very good and sometimes the finished product was not as desired.

The size of the output at a time was increased, greatly reducing labor and time. Output could be done at a level that did not require post-processing such as scraping off and polishing. In addition, coloring work is no longer necessary and colors can be expressed as they are in the 3D data, expanding the range of applications and making it possible to realize a variety of offers.

Product installed

Challenges

Improvements

The Mimaki's JFX200 that was previously in our operation was a really good printer. While using it, I wanted a printer with even more productivity.

The JFX600, which supports a variety of print modes, is capable of printing approx. 15 full-size board per hour with even high image quality. And like the JFX200, its ease of setting media of various shapes and the repeatablity of print position accuracy were desitive factors in the investment.

Product installed

Challenges

Improvements

Want to switch from traditional craft production to a new business

In four years, acrylic goods sales have grown to 80% of total sales!

Product installed

Launched an online store for Photography Background Sheets: Maekawa Printing Inc.

Challenges

Improvements

Want to expand the business type that has grown during the COVID pandemic.

The company has expanded the scope of its operations through the introduction of the UCJV300 and other equipment. They plans to continue to grow its digital printing business.

Product installed