MIMAKI INDIA PRIVATE LIMITED

3DUJ-553

Case Study

Challenges

Improvements

In addition to output by 3D printer, post-processing such as polishing and coloring was time-consuming. Also, the hue were not very good and sometimes the finished product was not as desired.

The size of the output at a time was increased, greatly reducing labor and time. Output could be done at a level that did not require post-processing such as scraping off and polishing. In addition, coloring work is no longer necessary and colors can be expressed as they are in the 3D data, expanding the range of applications and making it possible to realize a variety of offers.

Product installed

How Mimaki’s Full Color 3D Printer is Revolutionizing the Footwear Design Process

Challenges

Improvements

In the design and development of new products for footwear brands, it took more than a month from the time the order was placed to the time the prototypes were received. Also, it was taking time for the design idea to take shape and be put in the hands of the designer.

With the 3DUJ-553, a 3D design model of a shoe can be printed in one to two days, significantly shortening the time required to create a prototype, which normally takes more than one month. In addition, the process from design modification to prototype production can be repeated more times in a short period, leading to better product creation.

Product installed

Collaboration

Efforts of Mimaki

Students from CREAPOLE design school in France participated in a 3-day shoe design workshop hosted by Adobe and On, a performance running shoes company. The winning designs were printed by Mimaki and awarded to the students.

Using the 3DUJ-553 to bring the students' shoe designs to life.

Product used

Fansea creates unique virtual and 3D printed memorabilia using Mimaki technology

Challenges

Improvements

The business of the German start-up company Fansea is based on 3D asset creation, web3 and metaverse consultancy. Fansea was searching for a technology to bridge the gap between the virtual and physical by offering their customers photorealistic, 3D copies of their digital assets.

3DUJ-553 can accurately bring the individual qualities of each item directly from the screen to the model. 3D printing has the potential to revolutionise the digital space.

Product installed

Challenges

Improvements

When necessary, the Creative Design and Additive Manufacturing Lab at the University of Auckland added color to 3D prints by hand due to the lack of vibrant colors and affordability in full-color 3D printers.

The Mimaki 3DUJ-553 full-color 3D printer now allows the Lab to print in 10-million colors at a running cost affordable to the university.

Product installed

Challenges

Improvements

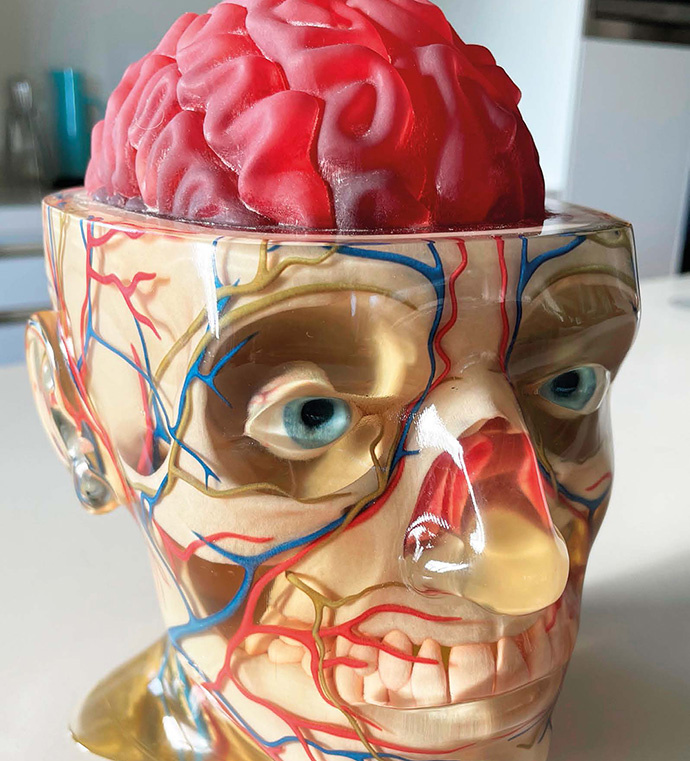

Low color accuracy, fragile parts, and time intensive post processing produced less than desirable results with powder based full-color 3D printing.

The full-color 3DUJ-553 creates robust anatomical models with realistic color reproduction that are easy to post process.

Product installed

Collaboration

Efforts of Mimaki

Collaboration between The University of Florence and Mimaki’s Italian importer Bompan results in a milestone for anatomical study.

The full-color “3DUJ-553” 3D printer was used to reproduce a 3D scanned human heart with high color accuracy.

Product used

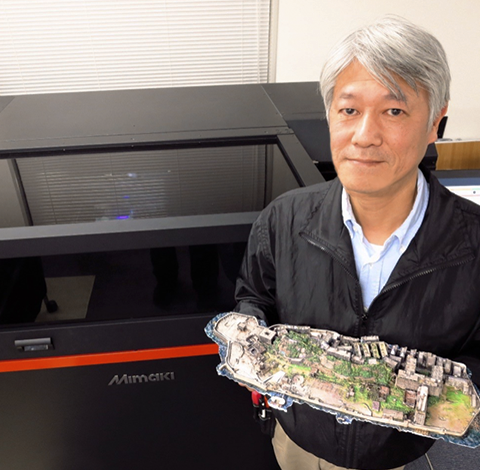

Collaboration

Efforts of Mimaki

Collaborated in the creating a high-precision replica of "Tsunagi no Ryu" with Chichibu Shrine, HARA SEISAKUSYO Co., Ltd. and Kouwa Display Co., Ltd.

Using full-color 3D printer "3DUJ-553" to faithfully reproduce "Tsunagi no Ryu" by "Hidari Jingoro" of Edo's master craftsmen

Product used

3D printer to support local Nagano sport teams! Created 3D printed objects with a large 3D printer

Collaboration

Efforts of Mimaki

3D printer to support local Nagano sport teams!

Using the 3DGD-1800, a large 3D printer, we produced and presented Shinshu Brave Warriors "Life-size figure of Wayne Marshall" and AC Nagano Parceiro "Ball stand".

Marketiger B.V. (Eindhoven, Netherlands) | 3D Printer Special website

Challenges

Improvements

I started my 3D business with monochromatic 3D printers, but was struggling to keep up with demand due to the amount of post processing involved to add color. We examined a powder based full-color 3D printer, but found that the material was too fragile and the color faded within one year, so we decided it wasn't the right option for us.

The introduction of 3DUJ-553 eliminated the need for manual coloring work and made it possible to create molded objects in a short time with materials that had rich color expression.

Product installed

Okumura Design Corporation (Nagoya City, Aichi) | 3D Printer Special website

Challenges

Improvements

We were looking for 3D printers capable of outputting high definition 3D data created in the office for use in explaining construction processes to our clients.

The model prototypes were extremely popular and we successfully landed requests for proposals. As 3D printers can reproduce models cheaply in diverse scales, they are better than outsourcing hand-crafted models, and we are confident they will become indispensable as effective business tools.

Product installed

Hotaru Corporation Co., Ltd. (Osaka-shi, Osaka) | 3D Printer Special website

Challenges

Improvements

Although the company already had a full-color 3D printer, the plaster-based type needed to go through processes that almost required artisan skills such as polishing and re-coloring for modeled objects before they become products.

3DUJ-553 has enabled more than 10-million color representation that is fine in details, in addition to real, delicate expression that needs no re-coloring. As the support material is water-soluble, we can remove it easily by soaking the object in water, which allows us to work on details to the last minute, enabling a wider range of expression than ever before.

Product installed

JMC Corporation (Yokohama, Kanagawa) | 3D Printer Special website

Challenges

Improvements

Although we already had a plaster-based full-color 3D printer, we did not accept orders with colors because it was extremely difficult to finish the works with colors satisfactory to clients. However, our valued client requested us to deliver figures finished with colors.

3DUJ-553 is highly valued by clients for its excellent color reproducibility. Because there is no need to provide coloring experts and thus 3D-printed products can be delivered as finished items, the company has propelled the business a step ahead without making unnecessary investment.

Product installed

B&P Co.,Ltd. (Osaka-shi, Osaka) | 3D Printer Special website

Challenges

Improvements

We wanted opportunities to meet new clients of different types, such as those ordering large-size posters and signs, POP display for promotion.

We came to receive orders and sample requests from companies manufacturing souvenirs, amenities and original goods, resulting in acquisition of new clients.

Product installed

Popls Inc. (Fussa-shi, Tokyo) | 3D Printer Special website

Challenges

Improvements

We used to mainly create figures with a plaster-based 4-color printer that enables color printing, but came to want to challenge a full-color 3D print with a higher definition.

It is highly received by clients dealing in 3D modeling artworks as well. Mimaki's "3DUJ-553" enabled us to demonstrate what the advance 3D print is like. Introduction of "3DUJ-553" also had a positive impact on the overall company.

Product installed